1、 Introduction to the experimental cabin This test chamber can be used to test the removal efficiency of purifiers on particulate matter, gaseous pollutants, and microorganisms in the air. Used to evaluate technical indicators such as purification efficiency, purification level, and purification life of products. 2、 Design reference standards GB/T 18801-2022 “Air Purifiers“ GB 21551.3-2010 “Special Requirements for Antibacterial and Sterilization Function Air Purifiers for Household and Similar Electrical Appliances“

+8675526585726

13609623361@139.com

DESCRIPTION

One,Introduction to the experimental cabin

This test chamber can be used to test the removal efficiency of purifiers on particulate matter, gaseous pollutants, and microorganisms in the air. Used to evaluate technical indicators such as purification efficiency, purification level, and purification life of products.

Secondly,Design reference standards

GB/T 18801-2022Air PurifierGB 21551.3-2010Special Requirements for Antibacterial and Sterilization Function Air Purifiers for Household and Similar Electrical Appliances

Three,System Composition

serial number |

name |

Instructions |

1 |

Main box body |

framework50×50×1.5mmStainless steel frame flooring:SUS304Mirror-finished stainless steel1.5mmTop plate:SUS304Mirror-finished stainless steel1.5mmSide view:10mmInstallation around the bottom of tempered glass4A pulley |

2 |

sealing performance |

Using airtight doors, airtight switching valves, sealed sampling ports, etc., gas leakage is less than5% |

3 |

sampling port |

aperture17mmUsing rubber plugs for sealing; |

4 |

intake and exhaust |

Install butterfly valve (one in, one out)+On/off control of pipeline fan |

5 |

Wiring hole |

Sealed with waterproof joints. |

6 |

fan |

Top mounted mixing fan (three blade) |

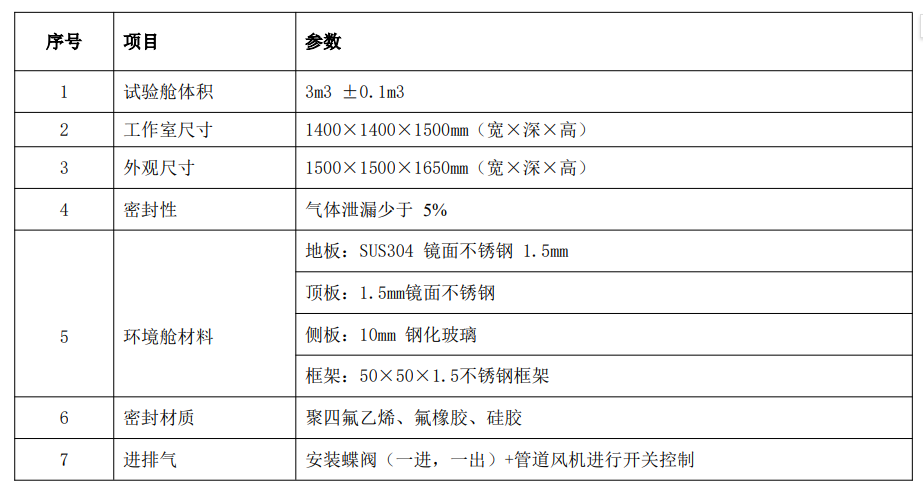

Four,Specifications

Air inlet and exhaust device

Equipment composition: Circulating fan, pipeline, medium efficiency filter, high-efficiency filter

Fan (technical parameters): air inlet/exhaust fan

Material: The circulation pipes are made of stainless steel material;

Equipment installation: Entering/Add an air filtration system to the air outlet section

Installation process: All connection parts of the pipeline are sealed with sealing strips and glass silicone gel

Equipment Introduction

1Equipment Introduction: This experimental system consists of a laboratory, an air circulation device, an exhaust system, a sampling device, and an electrical control system for the equipment.

2The test method is mainly divided into: natural attenuation test and total attenuation test

The natural attenuation test is as follows:

1)Place the air purifier to be tested on the test bench in the middle of the laboratory (except for vertical air purifiers), adjust the air purifier to the working state, check if it is running normally, and then turn off the air purifier;

2)Arrange the sampling points in a location that avoids the air inlet and outlet, and is at a distance of from the wall0.5mThe relative height of the laboratory floor is0.5~1.5mOne or more sampling heads can be installed at the same sampling point and connected to external sampling tubes;

Close the exhaust duct air valve, open the internal circulation duct air valve, start the auxiliary fan, and use a high-efficiency filter to purify the air in the laboratory, so that the particle diameter is 0.3MmThe above

3)The particle background concentration is less than one thousandth of the initial detection concentration, while detecting the air temperature and humidity in the laboratory;

4)When the background concentration of particulate matter decreases to an appropriate level, record the current background concentration of particulate matter, turn off the circulating fan and high-efficiency filter, start the household ceiling fan, and use the sampling device to place the smoke pollutant in the laboratory and allow it to enter the air vortex generated by the ceiling fan stirring10minAfter the pollutants are mixed evenly, turn off the household ceiling fan;

5)After the ceiling fan is completely stopped, use a laser dust particle counter to measure the concentration of pollutants, usually at the beginning of the test 0.3MmThe particle concentration of the above particles is 2000000 a/L

Left and right, the value of the test point is used as the initial concentration in the laboratory;

6)After the initial concentration is determined, the testing experiment begins. During the testing process, the concentration of pollutants is2minCollect together, contact for determination20minAt least one is required 9 The concentration of a data point is greater than the lower limit determined by the instrument 2 Double;

7)Record the laboratory temperature and humidity during the experiment;

8)Based on the measured data, the natural attenuation constant can be calculatedKn;

Total attenuation test

1)According to the above(1-4)Regulations for conducting experiments;

2)After the household ceiling fan is completely stopped, use a laser dust particle counter to measure the concentration of pollutants. Generally, at the beginning of the test 0.3MmThe particle concentration of the above particles is 2000000 a/L

Left and right, the value of the test point is used as the initial concentration in the laboratory;

3)After the initial concentration is determined, turn on the air purifier to begin the detection test. During the detection process, the concentration of pollutants is not affected2minMeasure once, continuously measure20minAt least one is required 9 The concentration of a data point is greater than the lower limit determined by the instrument 2 Double;

4)Turn off the air purifier and record the laboratory temperature and humidity during the experiment;

5)Based on the measured data, the total attenuation constant can be calculatedKe;

INQUIRY

+8675526585726

13609623361@139.com