Air purifier test chamber (UL867, portable household electric indoor air purifier), according to standard: ANSI/AHAM AC-1/UL867

+8675526585726

sales@damslab.com

DESCRIPTION

The environmental test chamber can simulate indoor environments and is an important tool for detecting and researching indoor air purification products. At present, foreign environmental chambers mostly focus on studying the release patterns of pollutants from indoor decoration materials and products, with little research on the detection of air purification products.

This product28.5m3Large environmental test chamber, with an inner wall of8mmFloat glass, the sealing material is a special sealant with low adsorption. The air purification system inside the cabin is equipped with a multifunctional air filter, which can remove both particulate matter and chemical pollutants such as formaldehyde, benzene, and ammonia. Moreover, the temperature and humidity control of the cabin is precise, the airtightness is good, and the background concentration of the cabin is low.

1. Overview of Environmental Test Chamber ANSI/AHAM AC-1-2006 Appendix A Normative Appendix

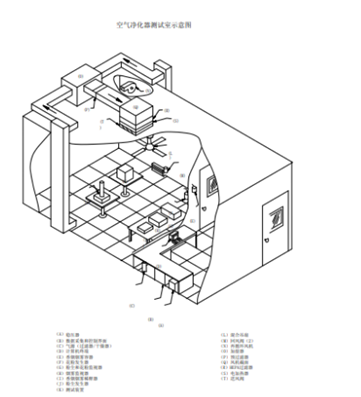

The overall structure of the environmental test chamber mainly consists of the cabin body, air purifier, exhaust duct, circulation duct, and air sampling system. The basic structure is shown in the following figure:

Structural diagram of glass cabin

2、 The main components of the test cabin system

2.1 Testing Room

There is a 28.5 cubic meter testing chamber installed in the testing room, and the size of the environmental testing chamber is 3200D × 3700W × 2400H mm

2.2 Observation Room

Used for observation during the experimental process, storage of test prototypes and experimental records

2.3 Test Cabin

Made of 304 stainless steel and glass, with a capacity of 28.5 cubic meters.

2.4 Glass cabin floor (pre embedded power/grounding circuit), made of 0.8mm thick SUS304 stainless steel material; The top ceiling is made of 0.8mm thick SUS304 stainless steel material.

The glass cabin is reinforced with stainless steel square bars and a wall made of 8mm float glass.

2.6 Doors, with a door opening size of 2000Hx800Wmm. The sealing adopts tetrafluoroethylene strips and sealing strips (HBC1079 food grade sealant has passed the EU ROHS environmental protection standard, passed the EU REACH chemical regulation standard, and passed the US FDA food hygiene level standard).

2.7 Homogeneous fan, 1.54m diameter ceiling fan

2.8 Injection and sampling holes, four sampling holes with a diameter of ¢ 6mm installed on the same plane as the door, equipped with valves, with a height distance of 1.0-1.2m from the ground surface and a spacing of 10cm. There are interfaces inside and outside the sampling port to match the required length of PTFE sampling tube, which can position the sampling point at different sampling positions. Install two injection holes with a diameter of ¢ 10mm in the opposite direction to the door, with a height of 1.0-1.2m from the ground. There are interfaces inside and outside the sampling port that can be matched with the required length of PTFE sampling tube

2.9 Top lighting, fluorescent lamp 40Wx2

2.10 Test Cabin Power/Control System

2.11 Operation console, controlling the main power supply, background purification system, lighting, ceiling fan, test start/stop, etc

2.12 The air circulation in the environmental chamber is mainly achieved by opening the test chamber air valve and turning on the variable frequency fan through the control panel. The air generates positive pressure through a variable frequency fan and enters the internal circulation. After passing through the variable frequency fan, the air with suitable temperature and humidity enters the multifunctional air filter. Finally, clean air is sent into the test chamber through the air valve, and the mixing fan at the top of the test chamber forms irregular vortices to accelerate gas mixing, leaving no dead corners in the chamber. After several cycles, the required cleanliness level for the experiment is achieved.

2.13 Air purification system (customer's own configuration)

Test the circulation inside the cabin, with a maximum air volume of 1800m3/H, including:

2.17 Filters: Junior high efficiency filter, HEPA filter, activated carbon filter, size: 500 (length) X500 (width) X50 (thickness) (cm)

2.18 Inlet and outlet: Control the inlet and outlet air volume through a frequency converter,

2.19 Fan: Variable frequency fan,

2.20 Pipeline: SUS304 stainless steel 1mm wall thickness 400x400mm pipeline, with shock-absorbing flanges used at the connection

2.21 The air purification system consists of a SUS304 stainless steel casing with an internal aluminum alloy filter track. It is installed with a plug-in filter structure that is easy to replace and maintain. The external dimensions of the filter are L500xW500xH50mm, including

2.23 Junior High Efficiency Filter: The efficiency of particulate matter passing through is 45%, filtering larger dust particles

2.26 The exhaust duct discharges residual pollutants after testing to the outside, with an air volume of 1000 m3/H,

INQUIRY

+8675526585726

sales@damslab.com